"Einstein of Structural Engineering" changes the face of architecture for good

Last updated: 10 October 2017 From the section Fazlur Rahman (F. R.) Khan

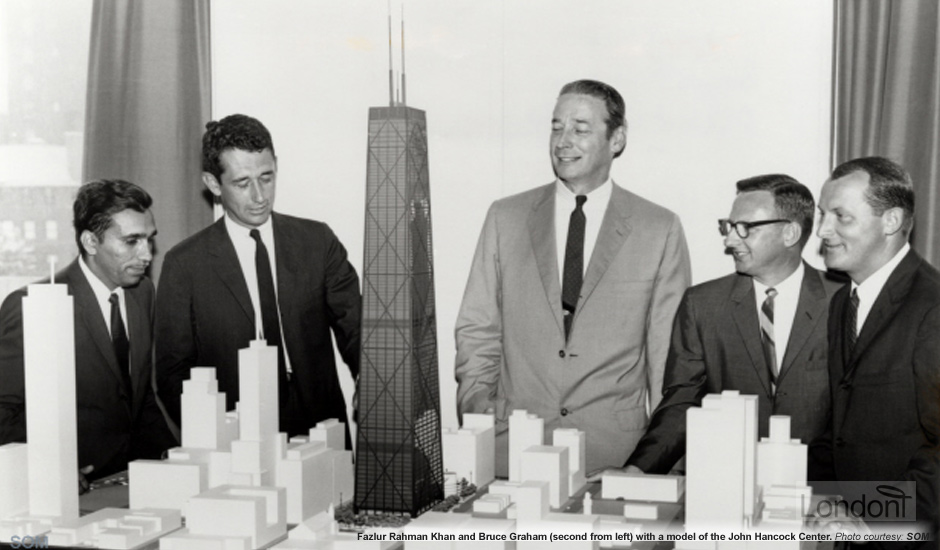

Fazlur Rahman Khan decided to make his home in Chicago. He rejoined Skidmore, Owings, and Merrill (SOM) in 1961 and became a Senior Designer in his first year there. But such was his achievement and blend of technical expertise and sense of aesthetics that Fazlur Khan rose through to Senior Project Engineer, to Associate Partner (1966), to Head of the Structural/Civil Division, and finally to a General Partner in 1970. He was the only engineer partner at the time out of a total of 20 partners at SOM. All the others were architects.

Bruce J. (John) Graham ()

Bruce J. (John) Graham ()  Stanley Tigerman ()

Stanley Tigerman ()  Myron Goldsmith ()

Myron Goldsmith ()  Hal Iyengar ()

Hal Iyengar ()  John Zils ()

John Zils ()

He could not have timed his return better. The Chicago office of SOM was large, busy and humming. Its design side was run mostly by architects trained under Mies van der Rohe at the Illinois Institute of Technology and known as the Mieslings. Brought up believing in structural expression combined with experiment, they were headed intellectually by Myron Goldsmith. Engineering, staffed increasingly by international recruits among whom Hal Iyengar should also be mentioned, was kept in-house, and collaboration between the disciplines taken as a matter of course. Khan, as he made his mark, embarked on a lifelong partnership with Bruce Graham, the architectural strongman of the office.

Andrew Saint reviews Yasmin's book "Engineering Architecture: The Vision of Fazlur R. Khan"

Initially he worked as an assistant engineer on a low-rise concrete building and a 22-story steel structure. Khan’s first job as project engineer was the 38-story Brunswick office building in Chicago. For it, he proposed the first shear wall-frame interaction design, a forerunner of tubular design. The building’s shear wall is connected to the outer frame with floor diaphragms to provide a bracing system against wind. "The Brunswick Building is built like a watch in the sense that we looked at everything that could ever go wrong," says Khan. As a result, he produced 500 charts to show its behavior under all conditions. This job also gave Khan his first professional jolt.

After lunch one day, Khan says, he received a phone call from the SOM chief engineer who said that the building was being shored because it was on the verge of collapse. Large cracks were spotted in the floor slabs. "I really felt nervous," says Khan, who is normally composed and confident.

Immediately Khan and others from SOM went to the building. To Khan’s relief, the cracks turned out to be slots cast in the slab’s corners, according to design, to relieve stress that was expected to develop during the building’s vertical expansion and contraction. "Boy, was I relieved. It was my first project and I thought my last".

Now, as partner, working with an engineering staff of 35, Khan says, "Wherever there is crisis, that’s where I am".

Richard M. Kielar, assistant editor of Engineering News-Record magazine

Fazlur Khan remained with SOM for the next 22 years, until his death in 1982.

Ability to 'connect' with innate objects

Soon after resuming work, Fazlur Khan achieved distinction by setting a new trend in the design of tall structures. The years of focused study as a youngster prepared him for a career characterised by innovation. He was particularly concerned with both the social and visual impact of buildings and was constantly searching for new structural systems to enhance a building's natural strength.

By the time he started to design tall buildings in the early 1960s, Fazlur Khan had a remarkable understanding of material and structural behaviour which allowed him to combine steel and concrete in innovative ways. He was able to think creatively, venturing beyond the conventional methods of analysis and design, as well as an intuitive understanding of structural behavior and load flow. Fazlur Khan became a great structural artist whose understanding of buildings was unsurpassed.

I had a visual feeling of what is going on... a kind of empathy to the structure.

Fazlur Rahman Khan on his ability to connect with his surroundings

His personal and professional grounding allowed him to be open to the probing of ideas and the give and take of working with others. His ability to participate in design as fully as he did owed much to his eagerness for communication.

My father felt strongly about people working together as a team, toward a common goal. This attitude, it seems to me, partly explains his comfortable way of working with others. Design is a process fostered by "natural communication", he said. "If you start controlling design by hierarchy, it will never be done right; never natural". I heard from his associates that he applied this approach to design meetings, preferring collegial dialogue to hierarchically structured exchange.

Revolutionary "tubular systems" innovation redefines the limits of the skyscraper

When Fazlur Khan joined SOM on a permanent basis in 1961 the options available to designers of multistory buildings were limited. Up until then most buildings were built with very wide spacing of columns (about 10-16 feet) and long spans between them. These buildings were called (skeleton) 'framed' building and that was the system that was used for many many years. Alternatively, engineers could design shear walls in concrete construction, or shear trusses in steel construction, to resist lateral loads. This steel frame construction relied heavily on internal support column and bracing to bear all the structural load. The size and number of these column directly correlated with the height of the building, and this technique was appropriate for buildings up to 20 or 30 stories. As building became taller, the frame system was becoming very inefficient and the unit area cost increased disproportionately to building height. A good example of this is the Empire State Building with its very large quantity of structured steel.

However, Fazlur Khan was about to turn the construction industry upside down. He was a firm believer that meshing the talents of structural engineers and architects always resulted in the best solutions and was intent on finding solutions that would reduce the amount of structural steel or concrete necessary to support a huge skyscraper, and thus making large towers economically feasible.

Architectural goals makes the engineer more conscious of the need to design the structure as efficiently, elegantly, and articulately as possible.

The greatest step the building team has made in the past decade is that the engineer, as part of that team, is finally looking at the whole structure with architecture integrated as part of the whole. This group thinking results in a systems building that satisfies all requirements.

The population explosion, beginning with the baby boom of the 1950s, created widespread concern about the amount of available living space. Khan had the solution — building up! The tallest building in the world at that time was the Empire State Building, a massive 102-story steel-frame structure. Khan would top this building, and in his quest to do so would re-shape the concept of super-tall buildings and man’s ability to live and work in the sky.

Christina M. Zweig of 'Structural Engineer' magazine

In 1963 Fazlur Khan came up with the idea of bringing the exterior columns closer together so the columns would act like a wall or simulate a thin-walled tube at the perimeter of the building. The building's external "skin" could - provided it had enough trussing, framing and bracing - act as the structure itself and would consist of several vertical skeleton sections, or tubes, combined into one building where the building perimeter would be used to resist lateral loads. This would result in greatly improved strength and stability (notably greater resistance to lateral forces), while using less steel. It would also minimise the need for massive support column at the center of the building, thereby increasing floor space.

It's a three dimensional space structure composed of three, four, or possibly more frames, braced frames, or shear walls, joined at or near their edges to form a vertical tube-like structural system capable of resisting lateral forces in any direction by cantilevering from the foundation.

Think of Fazlur Khan tube system as like a huge bendable spine, made up of connected frames.

Neil Collins, Writer

The first buildings to utilise Fazlur Khan's patented tubular concept was the DeWitt-Chestnut Apartments and the Brunswick Building, both in Chicago. Lateral stability was achieved by closely spaced columns placed around the building and connected together by deep beams, like a wall with holes punched though it for windows. This paved the way for the tube structure used by Minoru Yamasaki in the construction of buildings 1 and 2 of the World Trade Center (1965-66).

Khan’s initial work at SOM involved prestressed concrete - the topic of his doctoral thesis - but when opportunities arose to design a 37-story reinforced concrete office tower and a 43-story apartment building, he gladly seized them. The 37-story Brunswick Building in Chicago was expected to obtain its lateral stiffness from shear walls at its core. As design progressed, however, Khan recognized that the selected column spacing resulted in stiff beam–column frames. Although the shear wall and frame systems were not commonly combined, he decided to allocate a portion of the lateral load to the frames. More important, he drew on his experience with this design to suggest the use of an interacting system for other buildings. Dedicating long hours to preparing practical design aids, he instituted a life-long practice of sharing his ideas for design, along with recommendations for analysis of the new structural forms, by way of professional publications and lectures.

Usable in both steel and concrete buildings, the 'tube concept' revolutionised tall building design. During the next five years Fazlur Khan expanded the tubular system to develop an astonishing number of new structural systems including the "tube-in-tube", "framed tube", "trussed tube (or X-bracing)" and "bundled tube" designs. These new systems provided strength and stiffness with minimum premium for height and were made possible by new technologies, such as more advanced software and new developments in steel. These structural systems remains to this day. Most buildings over 40-storys erected since the 1960s now use Fazlur Khan's tube design, not least because tubular systems provide greater interior space and facilitate a greater variety of building shapes.

In the 1970s, computer methods for structural analysis were just beginning to be used on a large scale. SOM was at the center of these new developments, with undeniable contributions from Khan. Although Khan fully embraced this new technology, his cautious and methodical nature was seen in his insistence on laboratory tests at the University of Illinois for a three-span continuous transfer girder, measuring 8 feet wide by 24 feet deep, for the Brunswick Building in Chicago. Khan believed the scale of what he created was still beyond the capacity for which current analytical theory could be trusted.

Christina M. Zweig of 'Structural Engineer' magazine

Initially Fazlur Khan refined his tube concept to come up with the "tube-in-tube" system where the second tube is formed by the interior "shear walls", which are the concrete walls surrounding the building core. This technique was used for the 52-story One Shell Plaza Building in Houston. Later, the framed tube system enabled Fazlur Khan to design constructions capable of resisting the strong wind forces more effectively by having the forces absorbed by all three dimensions of the building (trussing, framing and bracing). The diagonals, connected to the exterior columns, allow the forces to be carried from the braces to the columns and back, and roughly half the exterior surface is made available for windows. The innovative construction, like other tubular designs, used far less steel than the traditional rigid steel-frame structure and resulted in a 50% decrease of required steel compared to skyscrapers built with interior columns. The Empire State Building (1931), for instance, consumed 206 kilograms of steel per square metre, whereas the John Hancock Center, the first building to use Fazlur Khan's trussed tube concept, needed only 145 kilograms of steel per square metre.

Other world famous skyscrapers built using the X-bracing system include the Onterie Center in Chicago (1985, which is an example of such a system in concrete), the Citigroup Center in New York (1977, later renamed to 601 Lexington Avenue), and the Bank of China Tower in Hong Kong (1990).

Considered to be one of the most famous examples of the structural expressionist style (the anti-minimalist idiom also known as decorative formalism), the [John Hancock Center] tower's distinctive X-bracing facade exemplifies the technique of using a building's formal elements for both engineering and aesthetic purposes. In this case, aside from its decorative attribute, the X-bracing is part of the tubular structure.

Neil Collins, Writer

The "bundled tube" structure is even better for supertall tower buildings. It gives the ability to support a number of different shapes which could be "bundled" together in a variety of groupings. This meant a supertall skyscraper no longer had to be shaped like a rectangular box and could be more creative. Fazlur Khan's "ingenious" bundled tube design (as described by Time magazine) was first applied to the construction of Chicago's 110-story Sears Tower, one time the tallest building in the world for 25 years. Another famous example is One Magnificent Mile (1983), popularly known as One Mag Mile, also in Chicago, while the One Peachtree Center (1991) in Atlanta is an example of a concrete bundled tube design.

Khan's innovative approach brought together narrow, silo-like structures to form a thicker tower, thus doing away with the conventional skeleton frame.

First designer of the Sky Lobby

Fazlur Khan designed the first sky lobby, which he incorporated into the John Hancock Center. A sky lobby is an intermediate floor where people can change from an express elevator that stops only at the sky lobby to a local elevator which stops at every floor within a segment of the building. When designing very tall (supertall) buildings supplying enough elevators is a problem - travelLers wanting to reach a specific higher floor may conceivably have to stop at a very large number of other floors on the way up to let other passengers off and on. Sky lobbies reduce the number of elevator shafts required, while simultaneously maintaining acceptable travel times. Fazlur Khan's concept was later employed at the World Trade Center in New York (1973), the Petronas Twin Towers in Kuala Lumpur in Malaysia (1993-4), Taipei 101 in Taiwan (2004) and the Burj Khalifa in Dubai in United Arab Emirates (2010).

Khan's ideas for these sky-scraping towers offered more than economic construction and iconic architectural images - they gave people the opportunity to work and live "in the sky". Hancock Center residents thrive on the wide expanse of sky and lake before them, the stunning quiet in the heart of the city, and the intimacy with nature at such heights: the rising sun, the moon and stars, the migrating flocks of birds.

Conceptualised building for earthquake-prone or seismic zones

One of Fazlur Khan's less known contribution is his designing buildings to be earthquake-resistant. He came up with the concept of a shock-absorbing lower floor after an earthquake in Yugoslavia in the 1960s damaged the bottom story of many buildings.

A further innovation by Khan, and something that is not as well known, is his original concept of dissipating energy as the lower storey of buildings in seismic zones...He thought of a shock-absorbing soft-story concept in which a 'stability wall', consisting of neoprene pads, and deformable cables would be used in the lowest most level in a predetermined fashion such that during an earthquake the lower level would dissipate energy and isolate the upper floors from any damage...Thus designing the entire building to resist high earthquake forces, the bottom story of the building is allowed to distort with earthquake, thereby screening out most of the forces there. The upper part of the structure remains unaffected and behaves as an elastic system, whereas the lower story behaves as an elasto-plastic bilinear system.

Mir M. Ali, author of "Art of the Skyscraper: The Genius of Fazlur Khan" (2001)

"Father of tubular construction"

For his groundbreaking concept Fazlur Khan was known as 'Father of tubular construction' or 'Einstein of Structural Engineering' in the architectural world. He was the master of the tall order and became an icon in both architecture and structural engineering.

It was his unique ability to bridge the gap between architectural design and structural engineering that truly set Faz apart from other structural engineers.

John Zils, Senior Engineer and Associate Partner at SOM

Eulogized by the New York Times, the Chicago Tribune and Time magazine, among other publications, as one of the greatest structural engineers of modern times, Bangladesh-born Fazlur Rahman Khan is credited with designing some of the tallest concrete and steel buildings in the world.

Hyung-chan Kim, editor of "Distinguished Asian Americans: A Biographical Dictionary" (1999)

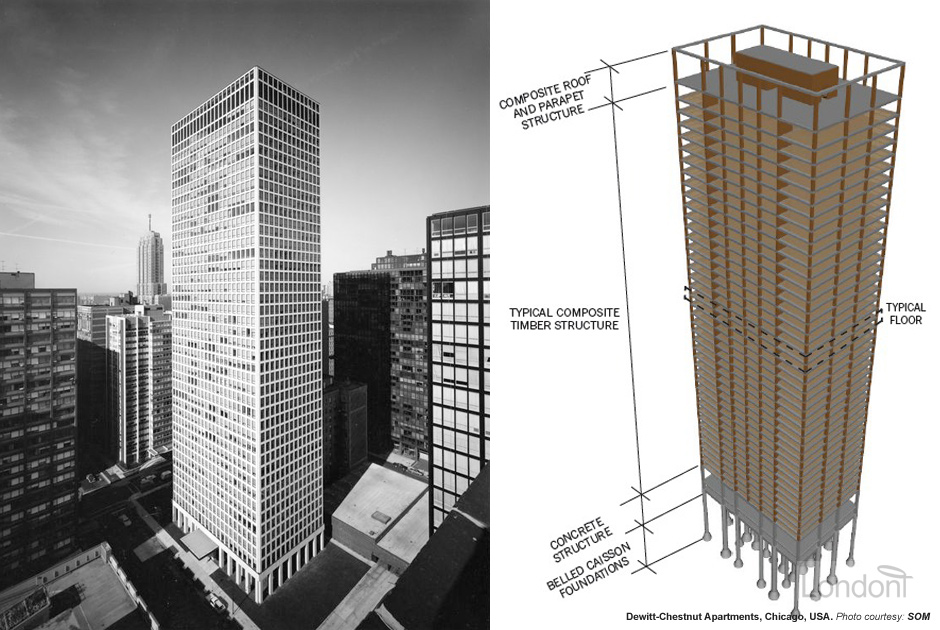

Dewitt-Chestnut Apartments, Chicago - the first building built using Fazlur Khan's framed tube structure

The first building to be built using Fazlur Khan's innovative framed tube structure was the 42-story (120 metres tall) Dewitt-Chestnut Apartments in Chicago in 1965. The residential building located at 260 E. Chestnut Street in the Streeterville neighborhood of Chicago represents a marked departure from his earlier thinking.

Initially, for economic viability and due to site restrictions, the building was intended to be concrete tower and was expected to derive its lateral stiffness from shear wall construction. But locating walls in the floor plan proved problematic and there was a severe limit on the length and number of shear walls to resist lateral loading. This forced Fazlur Khan to propose a completely new type of structural system. Bruce J. Graham, a partner and chief design architect in SOM’s Chicago office, was receptive to Fazlur Khan's idea for creating a perimeter shell of closely spaced columns and stiff spandrel beams to implement cantilever action of a three-dimensional structural form. This new structuring would resist the entire lateral loading and allow for more freedom in the placement of columns to account for vertical loads.

Closely spaced columns of reinforced concrete act with the spandrels to form an exterior tube and absorb all horizontal wind loads, allowing greater flexibility in the placement of interior columns and greater apartment layout flexibility. The exterior columns are spaced at 5 feet 6 inches on center and vary from 20 x 20 inches in the lower floors to 14 x 14 inches at the top of the building.

The decision was made to proceed with this system, and in 1965 Dewitt-Chestnut Apartments (also known as 'Plaza on DeWitt) became the first high-rise constructed as a "framed tube". The building contains 407 apartments, which were converted to condominiums in 1975, and is the tallest building in Chicago to be clad in travertine marble. It also has anodized aluminum window frames with tinted glass.

Many tall buildings still employ the framed tube structural concept in its design, including World Trade Center

Khan was quite excited about the new system’s dramatic advance in structural efficiency for high-rise design. Nevertheless, he acknowledged that inefficiency due to shear-lag limited its applicability. Convinced that the basic framed tube was not an optimal solution for buildings over 50 stories, at most 70 stories, he commenced his search for other systems.